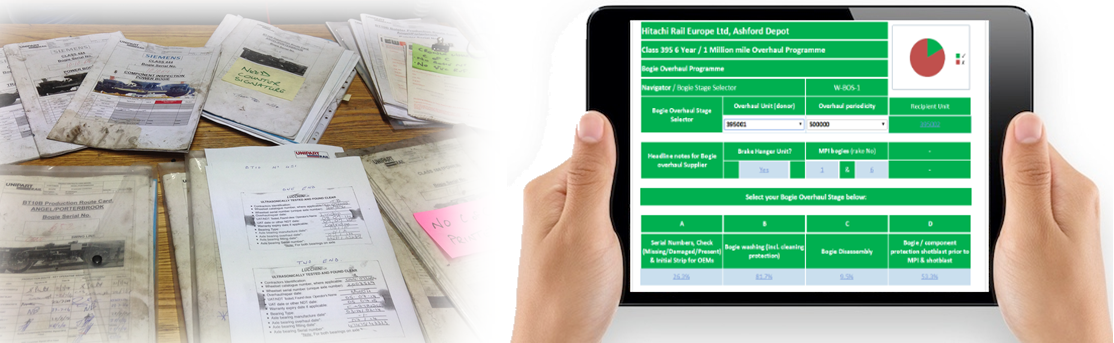

RIP Paperwork

ExcelWraps replaces all paper records at Unipart

A quantum leap for the Hitachi 395 bogie overhaul as paper is superseded by Wraps. Now information is immediately available through the cloud and shared across Unipart, with its clients and its subcontractors. Bogie overhaul consists of 20 main processes each having many sub-processes. Some 140 separate Wraps are required to cover every work procedure.

| 1. Serial Numbers & Initial Strip for OEMs |

| 2. Bogie washing |

| 3. Bogie Disassembly |

| 4. Bogie shotblast |

| 5. Bogie Frame & Component MPI |

| 6. Bogie Frame: component examination |

| 7. Bogie Frame: paint frame, components and post MPI components |

| 8. Primary Spring Overhaul |

| 9. Bogie Electrical Examination and Overhaul |

| 10. Bogie Electrical Assembly |

| 11. Axlebox overhaul: bore measurements |

| 12. Torsion Bar Assembly – overhaul |

| 13. Bogie Components – overhaul |

| 14. Bogie Assembly 1 |

| 15. Bogie Assembly 1 QA |

| 16. Bogie Assembly 2 |

| 17. Bogie Assembly 2 QA |

| 18. Bogie Pressing |

| 19. Pre Bogie Press Lift Off tasks |

| 20. Post Bogie Press Lift Off tasks |

Wraps respond intelligently as data is entered, guiding the workforce through the overhaul process. They pull information already entered in other Wraps minimising data entry and the risk of duplication errors. Wraps integrate with the Unipart Rail Competency Management system ensuring that only trained personnel can sign off particular jobs. Unforeseen work arising can easily be captured using the integral camera on tablet devices and a rectification plan can be agreed quickly with the client. Wraps run on PCs in the office, on tablet devices on the shop floor and from smartphones for those people caught on the road. A live pie chart shows the current % completion and supporting tables allow you to drill-down to any level of detail. Shop floor training has been completed in September 2014 and the system is now live.